Die Cast Tooling

Bedford Machine & Tool has over 30 years of experience in designing, manufacturing, and repairing die cast tooling.

In addition to complete designing and manufacturing of new die cast dies, we also provide: die rebuild, die refurbishment,

replacement components, new cavity inserts, and die repair services to all types of dies.

Bedford Machine has performed work on most types of aluminum dies, including:

- High Pressure die casting

- Low Pressure die casting

- Permanent die casting

- Semi Permanent die casting

- Forging Dies

Tell Me More

Large Machining

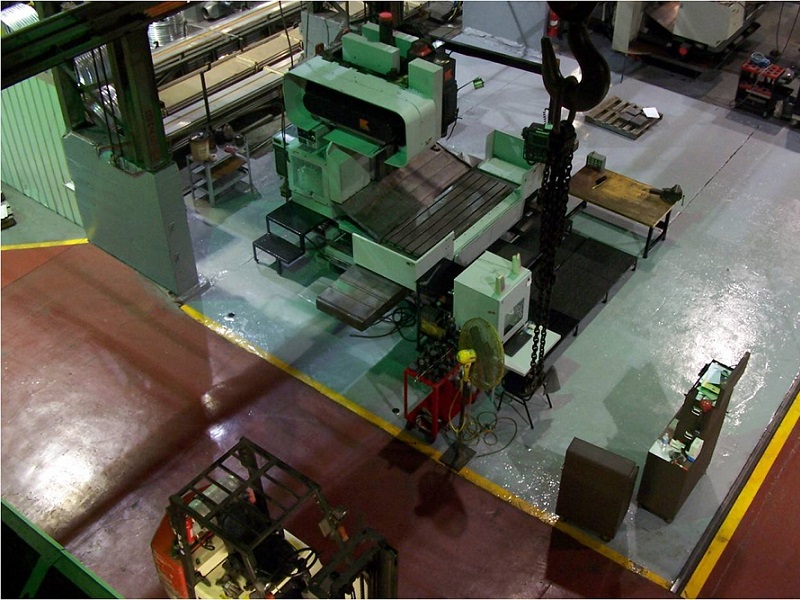

Bedford Machine & Tool’s horizontal milling capacity covers a full range of requirements for large manufacturing needs.

We have the capabilities and machine travels up to 10.5ft vertical x 47ft horizontal.

We have (6) large mills with vertical travels in excess of 80” and weight capacity up to 35 tons on our CNC rotary tables.

If smaller size and weight capacity is required, we offer horizontal high speed machining sizes of 49” x 41” x 32” with 15,000 RPM spindles.

With our available equipment, we can handle a wide variety of alternatives to meet the needs of our customers.

Tell Me More

CNC Production

Our Production Machining capabilities can meet most customer requirements.

We pride ourselves on being able to handle a wide range of parts. Large capacity CNC machining up to 10.5ft vertical x 47ft

horizontal, and small capacity CNC machining with various size machines and up to 20,000 RPM.

Our versatile production systems allow us to produce a variety of 1pc samples to thousands of parts per month.

We take pride in applying skilled trade machining techniques to meet your production needs.

Bedford Machine is ISO 9001 registered and offers versatile inspection and documentation of customer products via CMM’s and Laser Trackers.

We welcome you to visit our facility to see how we produce some of the most demanding parts in Industry.

Automation and Engineering

Providing mechanical / electrical engineering, manufacturing, electrical fabrication, hydraulic and pneumatic fabrication, run-off,

installation, and on-site services for custom automation and equipment. Please contact us for a quotation on your next project.

Our engineering staff can meet your needs with some of the most advanced technology in the industry today.

Bedford Machine & Tool engineers are experienced in: die cast die design, stamping die design, automated machinery, robotic end of

arm tooling, pick and place grippers, trim machines, leak testers, hydraulic and mechanical machining fixtures, CMM fixtures, gages,

conveyor systems, as well as work cell layouts.

We also have the skills and equipment to reverse engineer components for either manufacturing or to create a CAD database.

Unigraphics NX and AutoCAD are our primary CAD media. We have the required translators to import and export most software packages.

Tell Me More

Fabrication and Painting

Bedford Machine & Tool provides welding and fabrication product to our customers for a multitude of materials: aluminum, structural/mild

steel, and tool steels.

We follow NADCA specifications when working in the Die Cast Industry, and AWS D1.1 in the structural industry.

We offer MIG, TIG, Stick, Sub-Arc and Stud Welding.

Tell Me More